Powder Residue and the effect it has on your groups

Something to take into account when you’re at the range testing different batches of handloads.

Just to get things straight, Powder Residue, is the coating left in your barrel AFTER your last round was fired.

While teaching the intermediate reloading classes, I often get asked questions about the use of different powders and their appropriateness for a particular cartridge. As a result students create batches of cartridges with different powders for testing in their specific rifle. During these tests, mixed results become confusing resulting in follow up questions such as..

“I shot the same batch on a different day and obtained quite different results, how can that be?”

Here’s one cause that can really confuse reloaders.

I put together two batches of identical cartridges except for powder. One batch was using CFE223 the other Vihtavuori N133 powder.

After zeroing the rifle using CFE and letting the barrel cool during the shooting break, I shot 5 of the N133 loaded cartridges.

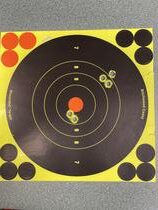

Take a look at the resulting target. The first 3 shots are grouped nicely about 1 o’clock 2 inches from my original zero. After these 3 shots, the next 2 shots returned to my Zero. The N133 batch took 3 shots to basically to overcome/replace the residue from the CFE223 powder with its own. (Yes, I stapled the target sideways. More on that some other time)

Therefore, if you are attempting to compare batches of cartridges.. note the following:

1) Only change 1 component at a time. (Changing 1 item per batch allows you to do a direct comparison, and SEE the difference)

2) Let your barrel cool between batches (Don’t shoot 1 batch with a Cold barrel and the other when it's HOT. Keep everything as consistent as possible)

3) If you are testing different powders, (Either...

A) Make 5 extra rounds and use them to break in the barrel with the second power (this replaces the previous power residue with the new one, OR

B) Clean the barrel AFTER you shoot the first batch). Again, keep the condition of the barrel as consistent as possible between test batches.

This should help solve this often-confusing occurrence.